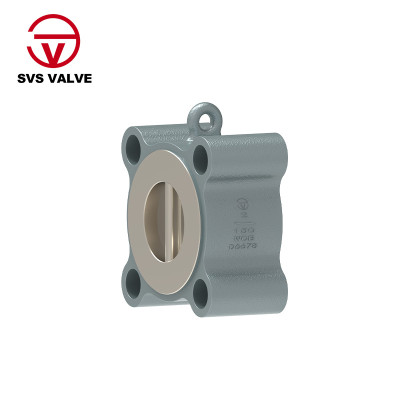

Our forged steel lift check valve is a robust and automatic valve designed to prevent medium backflow in your pipeline. The valve's disc is automatically lifted by the force of the fluid to allow flow and then lowers to close, preventing any reverse flow. This critical function protects pumps, motors, and other equipment from damage while ensuring the integrity of your system. Its forged steel construction provides superior durability and reliability for demanding applications.

How It Works: Automated Protection

This valve operates on a simple, effective principle: it opens and closes based on the direction of fluid flow.

- One-Way Operation: When fluid flows in the correct direction, the pressure lifts the valve disc, allowing for a clear, unobstructed path.

- Automatic Shut-Off: When flow stops or reverses, the weight of the disc and back pressure from the medium force the valve to close, preventing backflow. This rapid closing action helps to prevent water hammer and protect downstream equipment from damage.

Key Features

- Forged Body Durability: The forged steel body provides superior strength and corrosion resistance, ensuring a long service life and reliable performance under high pressure and temperature conditions.

- Minimal Flow Resistance: The design features a smooth fluid passageway, which minimizes fluid resistance and pressure drop, improving system efficiency.

- Water Hammer Prevention: The swing-type disc provides rapid and flexible closing action, which minimizes the impact of closing and helps to prevent water hammer.

- Compact Structure: The valve's compact and reasonable structure ensures reliable tightness and good performance in a small footprint.

- Damping Cylinder: An optional damping cylinder can be added to further prevent the effects of water hammer in critical applications.

Product Specifications

Body Material: Forged steel, stainless steel, alloy steel

Nominal Diameter: 1/4" to 2"

Pressure Range: Class 150 to 1500 (PN10 to PN420)

End Connection: RF (Raised Face), BW (Butt Weld), NPT (National Pipe Thread), SW (Socket Weld)

Working Temperature: -196°C to +560°C

Engineered to Industry Standards

Our valves are manufactured and tested to comply with the most stringent industry standards, guaranteeing quality and performance you can trust.

General Valve Design: BS1868, API6D, ASME B16.34

Flange Design: ASME B16.5

Butt Weld Design: ASME B16.25

Materials: ASTM