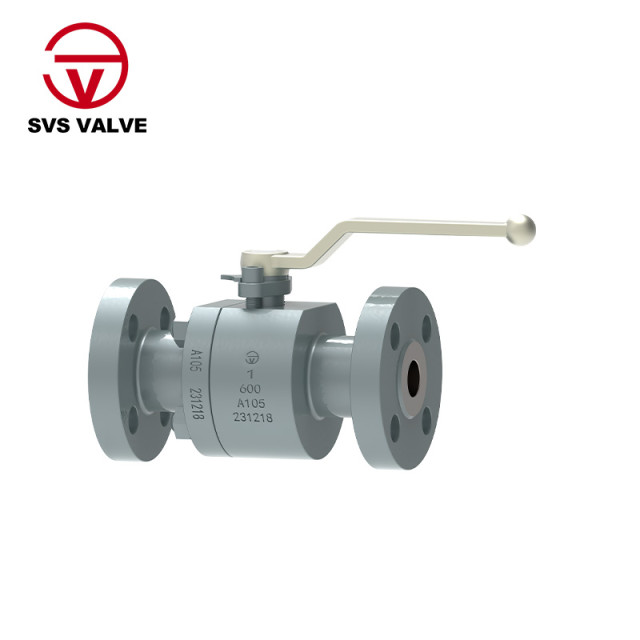

Our forged steel floating ball valve is designed to provide dependable, long-lasting fluid control in the most demanding industrial environments. Built with a robust forged steel body, this valve delivers exceptional durability and structural integrity, ensuring reliable performance in high-pressure applications.

How It Works: The Principle of Self-Sealing

This valve's design features a floating ball supported by two valve seats. Under the pressure of the medium, the ball generates a slight displacement, which forces it against the downstream seat seal ring. This simple yet effective principle guarantees a tight, bubble-free seal at the outlet, providing an extra layer of security in critical high-pressure systems.

Engineered for Safety and Efficiency

Our forged steel floating ball valve combines a rugged construction with a design that prioritizes safety and efficiency.

- Enhanced Safety: Standard features include a fire-safe, anti-static, and anti-blowout stem design. This protects your system and personnel from potential hazards in high-risk environments.

- Streamlined Flow: The valve is available in both full-bore and reduced-bore types, offering minimal flow resistance, which improves system efficiency and reduces energy consumption.

- Low-Torque Operation: A simple internal structure provides excellent tightness with minimal torque, ensuring smooth and effortless operation.

- Optional Features: An optional locking device and an ISO 5211 top flange allow for added security and easy integration with a variety of actuators.

Product Specifications

Body Material: Carbon steel, stainless steel, alloy steel

Nominal Diameter: 1/2" to 6" (DN15 to DN150)

End Connection: RF (Raised Face), RTJ (Ring Type Joint), BW (Butt Weld), THR (Threaded), SW (Socket Weld)

Pressure Range: Class 150 to 2500 (PN16 to PN420)

Operation: Wrench, worm gear, electric actuator, etc.

Standards & Compliance

Our valves are designed and manufactured to meet the most stringent industry standards, guaranteeing quality and performance you can trust.

Design: ISO 17292, API 608, BS 5351, GB/T 12237.

Materials: ASTM A105, ASTM A182-F6, F304, F316, F316L, F51, and other high-grade materials for key components.